Premier EDM Services including Electrode Construction

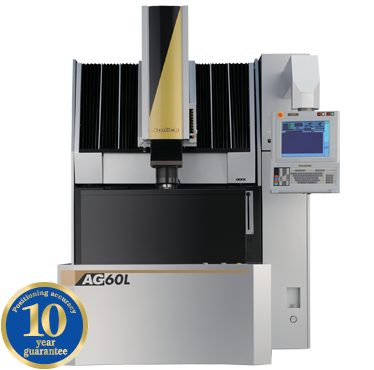

At Versatile Mold and Design, we specialize in precision Electrical Discharge Machining (EDM), delivering complex geometries and fine details that are difficult to achieve with traditional machining. Our in-house EDM capabilities are ideal for tight-tolerance applications across a wide variety of tooling for a broad range of industries. We have decades of experience using EDM as the backbone of our in-house mold and die manufacturing toolroom. We are also well positioned to use our modern, high speed EDM equipment to makes all kinds of precision components for the Aerospace, Defense, and Medical markets as well as general industry.

EDM Services Include:

Sinking/Plunger EDM for deep cavities and fine finishes

Wire EDM for precision cutting of intricate shapes and contours

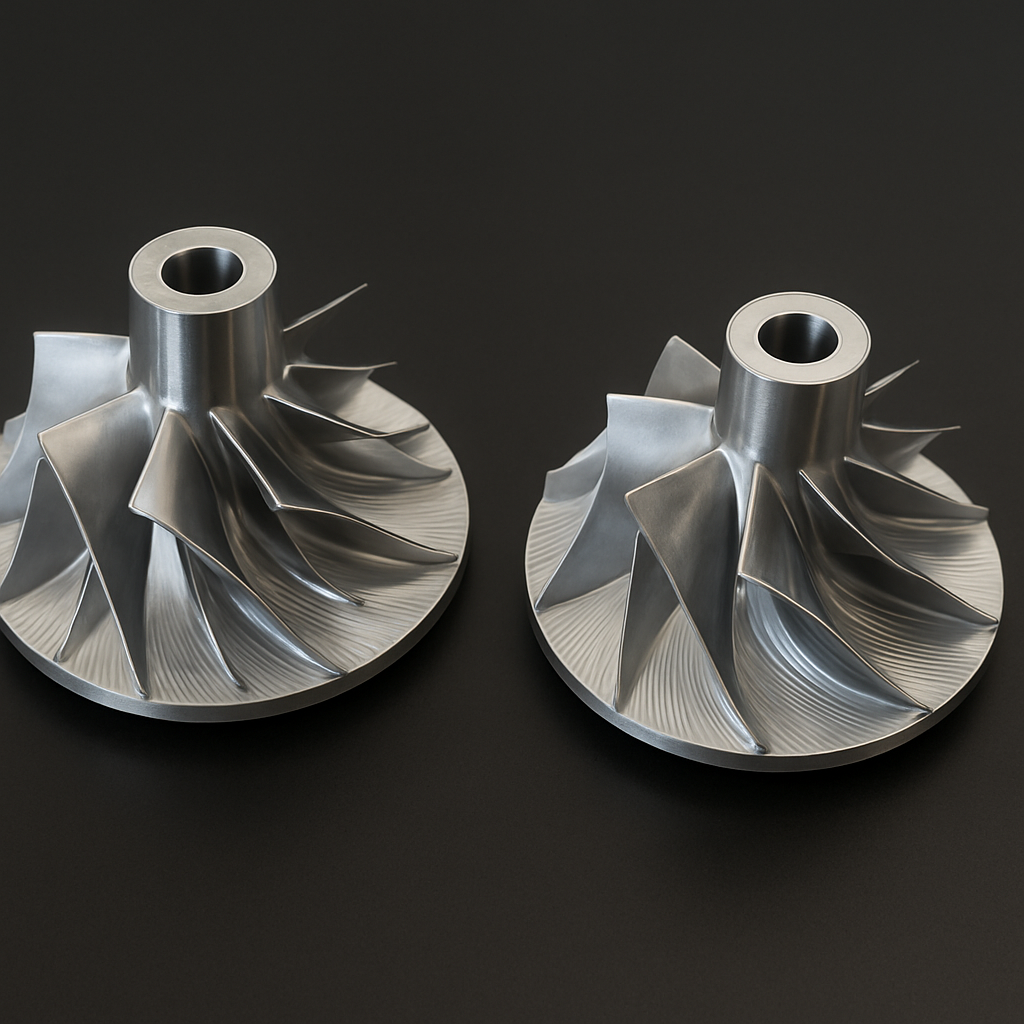

Electrode manufacturing using our specialized high speed, high RPM electrode machining centers

Tight tolerance machining, often within ±0.0002"

EDM machining of all types of hardened tool steels and exotic alloys

Custom Electrode Design & Fabrication

We don’t just run EDM machines, we also design and build custom electrodes to ensure every job runs with maximum precision and repeatability. Whether you need graphite or copper electrodes, our team uses advanced CAD/CAM software and CNC machining to craft the perfect match for your tool geometry and part design.

Electrode Capabilities:

Graphite and copper electrode fabrication

3D profiling and cavity matching

Electrode inspection using in-house scanning

Full inspection reports to meet your requirements

Electrode libraries to support ongoing production programs

Capability to run 24/7, if required to meet your demand

Production EDM Machining

Versatile Mold and Design can support your production requirements by manufacturing almost any quantity of high precision, high complexity EDM machined components. We can even scan the completed products to ensure 100% conformance to your specifications. Whether you need five components or five hundred, contact Versatile and work with our in-house technical team to see how we can make your project a success!