How Injection Molding Revolutionized Manufacturing

/Look around your desk. The chair, phone case, keyboard, and even your pen likely started in an injection mold. This is a behind-the-scenes method you rarely notice but rely on every day.

And the whole thing kicked off with a game of billiards and a $10,000 prize.

What an injection mold might have looked like in the 1800s

A quick origin story

Back in the 1800s, billiard balls were made from ivory. Demand climbed, elephants suffered, and a billiards company dangled a $10,000 reward (about $300k today) for a new material. John Wesley Hyatt stepped up with celluloid and a way to mold it. His balls didn’t bounce exactly like ivory, but his idea sparked modern plastic injection molding.

How injection molding works

At a high level, it’s this:

Melt plastic → Inject into a mold → Cool → Pop out the part.

In practice, a lot of smart engineering makes that simple loop run hundreds of times an hour with the same results.

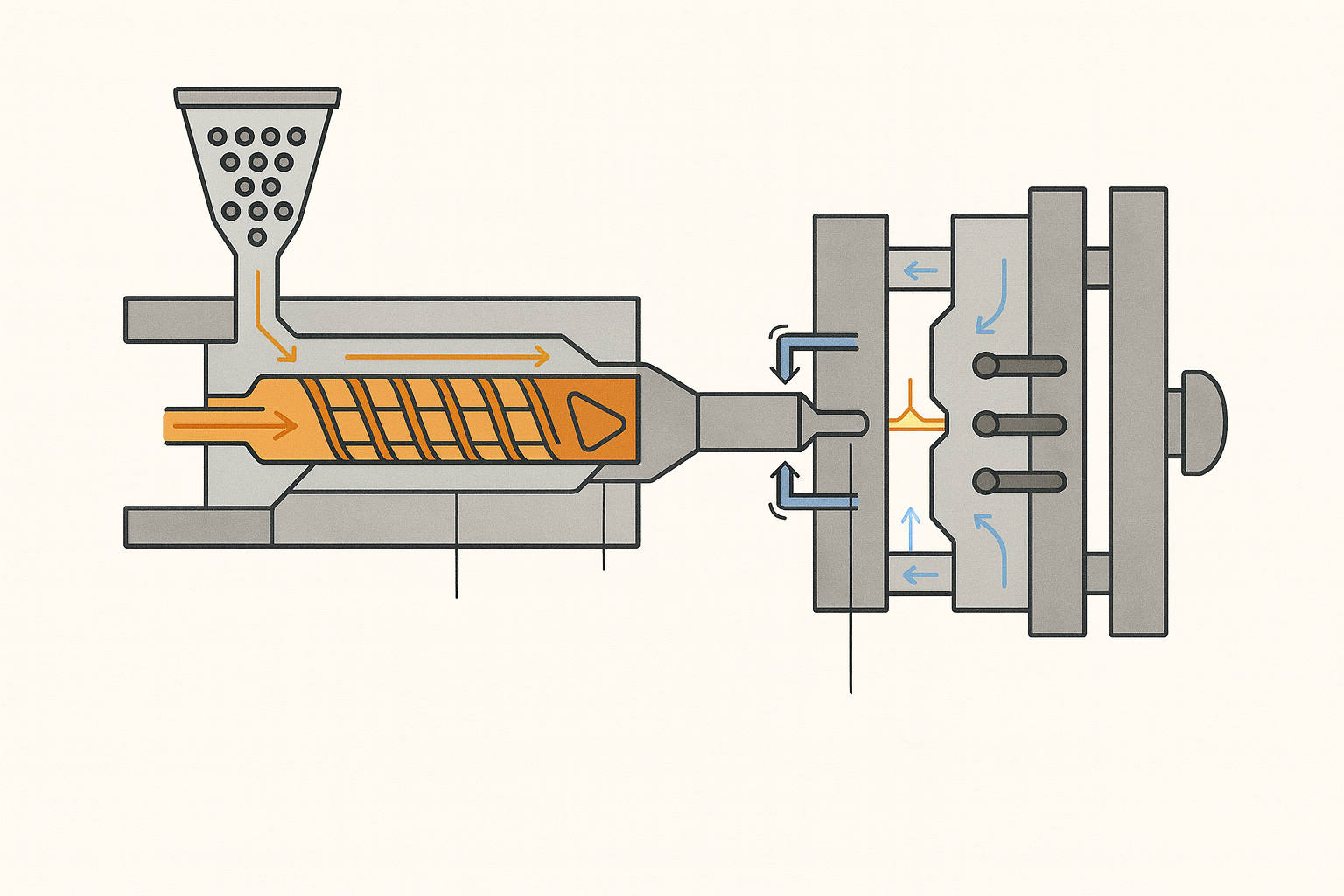

The three big pieces

Injection unit – melts and pushes the plastic

Mold – the precision tool that shapes the part

Clamp – holds the mold shut under pressure

The process

Pellets go into a hopper.

A heated barrel and a reciprocating screw melt, mix, and move the plastic forward.

The screw plunges like a syringe, filling the mold.

The part cools fast. The mold opens.

Ejector pins push the part out.

Repeat—often in under a minute.

Injection molding changed in the 20th century

Injection molding changed from a simple plunger to a screw-driven design. This new process allows the plastic to melt and mix more evenly. That upgrade delivers faster cycles, more consistent parts, and fewer defects at scale. It also paved the way for modern mold features and smarter flow systems you’ll see next.

The switch from plungers to screws in injection molds changed the process

Early machines used plungers and external heat. Plastic doesn’t conduct heat well, so the melt was uneven; too cool in the middle, too hot at the edges. The fix was the reciprocating screw:

More even melting: Plastic wraps the screw, so there’s no cold core.

Better mixing: The screw’s flights blend the material.

Smart heating: Screw motion adds shear heat, often most of the heat you need, so the melt is consistent.

Result: cleaner parts, tighter tolerances, fewer headaches.

How the plastic flows through the mold

Injection molding process

Plastic travels through:

Sprue: main channel

Runners: branching tunnels to each cavity

Gates: the entry points into the part

Want less trimming and less waste? Hot runner systems keep the plastic molten in the flow channels, so there’s little to clip and less scrap.

Inside the mold: a lot is happening fast

Vents let trapped air out (not plastic).

Cooling channels, usually water, set the part quickly.

A gentle first crack of the mold breaks the cooling vacuum.

Ejector pins push the part out, leaving tiny circular marks (you can spot them once you know to look).

Try this: flip over a plastic chair or check the edge of a disposable fork. You’ll probably see a parting line seam, a small gate mark, or those little ejector pin circles. Once you start noticing them, you see injection molding everywhere.

Precision is the point

Molding is fast, but the real win is making the millionth part match the first. Precision-built plastic molds and tight process control keep parts on-size, on-shape, and repeatable. That consistency comes from a few essentials such as how accurately the tool is cut, how evenly each cavity fills, what you measure while the press runs, and how you prevent defects before they start. Here’s how that plays out.

Tooling accuracy: Molds are cut to the thousandth of an inch. Small errors show up as warpage or fit issues.

Cavity balance: In multi-cavity tools, flow has to be even so every part is identical.

Inspection: Dimensional checks, surface inspection, in-mold pressure sensors, sometimes even CT scans for complex parts.

Defect control: Design and process tuning prevent sink, short shots, flash, and warpage; ideally before they ever appear.

From Hyatt to now

No official winner ever claimed that $10,000, but Hyatt’s work lit the fuse. Today, injection molding turns out billions of parts a year for medical devices, cars, electronics, furniture, toys, and more. The process keeps evolving with smarter materials, tighter tools, and better data, but the core idea still solves the same problem: make high-quality parts, over and over again.

Need a partner who lives this every day?

At Versatile Mold and Design, we build precision injection molds for the parts you rely on. If you’re sketching a new concept or fine-tuning a production mold, let’s talk through your goals and constraints first then we’ll map the right process and price.

Ready to start a conversation? Tell us about your part, the environment it needs to handle, volume targets, and any must-hit dimensions. We’ll come back with practical options and a path to production.